We test most brands of magnetic lifters

International Magnetic Solutions provides a fully-certified testing service for magnetic lifters available for most brands.

Depending on use we recommended that lifting magnets are tested every 6 to 12 months. If your lifting magnets are due for testing, get in touch with us to organise this service.

What we do

Our lifting magnet testing service provides:

- Technically qualified maintenance staff

- Tests for most makes of magnetic lifters

- Testing of the breakaway force of lifting and clamping magnets on a flat, mild steel test piece

- Visual inspection of lifting magnets for defects

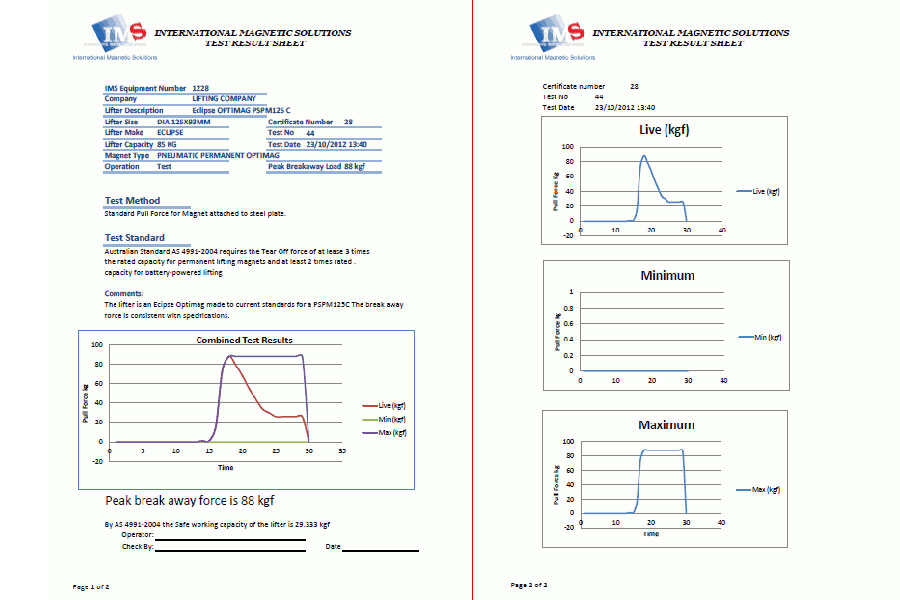

- Computer generated test certificate with graphical representation of the results

We can also:

- Test magnetic lifting equipment in special arrangements for specialist applications

- Take magnetic readings of the field strength of the magnetic device

- Maintain and repair magnetic equipment

Our reports

Computer generated Test Certificate with Graphical Representation of the results gives a clear representation of the Magnetic Lifter’s performance characteristics.

Each certification confirms the actual Magnetic power is sufficient to provide the rated SWL of the magnet (including safety factors) and that the construction of the lifter and its safety measures are Safe for use. You may be required to produce a certificate in the event of an incident.

Our test frame

Our specially manufactured testing frame is designed to allow a variety of testing arrangements for lifting and holding magnets in many standard and specialty applications.

This allows lifting magnets to be tested according to Australian Standard AS 4991-2004 which requires a tear-off force of at least 3 times rated capacity for permanent lifting magnets and at least 2 times rated capacity for battery-powered lifting magnets.

Our test equipment is certified

The Load Cells and Strain Bridge Meter are certified accurate by a NATA approved testing body.

The data from the Load Cell is transferred to a computer which produces Detailed Graphical Reports of the testing results which we provide for your records.

Magnetic lifter safety

Always check the lifting magnets before use

A pre-use check should always be conducted before a magnet is used. Check the operation of the handle, handle button, sliding key and security pin to ensure they are in good operating condition. Also check for excessive wear, corrosion or deformation of the lifting shackle. If there is any damage to the security function and it is no longer effective or the magnet has signs of deformation or excessive wear or corrosion the magnet shall be withdrawn from service immediately.

Always check the load condition before use

Place the magnetic lifter on the work piece surface in a position that will ensure an even lift.

The lifting capacity of the magnet is influenced by the thickness and surface finish of work piece. Before operation, it is necessary to inspect the work piece thickness to ascertain the likely lifting capacity of the magnet. Refer to the steel thickness lifting capacity curve shown on the side of the magnetic lifter and in the Operating manual.

One should also inspect the work piece surface finish. The magnetic lifter is designed for a smooth surface with full contact.

When lifting and handling cylindrical work pieces, the magnetic lifter should be placed on the cylindrical surface at a position where a balanced lift will be achieved. With a cylindrical surface the V-slot of the magnetic lifter contacts only along 2 lines hence the actual lifting capacity (SWL) of the magnet will be reduced to only 30-50% of the rated lifting capacity (SWL. The actual decrease of the lifting capacity is related to the diameter of the work piece being lifted.